Locating the Right Provider for Welding Inspection Madison: Secret Considerations

Locating the Right Provider for Welding Inspection Madison: Secret Considerations

Blog Article

The Value of Thorough Welding Evaluation in Industrial Applications

In the realm of commercial applications, the significance of careful welding evaluation can not be overemphasized. As we discover the multifaceted benefits of thorough welding examinations, one must think about the more comprehensive effects on safety, dependability, and cost-effectiveness in commercial procedures.

Enhancing Architectural Integrity

When it comes to welding inspection in industrial applications, enhancing architectural honesty is critical. The main objective of welding inspection is to make certain that the welds are qualified of bearing the anticipated anxieties and tons they will certainly run into in solution.

The value of preserving structural honesty in welded structures can not be overemphasized. Improperly performed welds can result in catastrophic failures, leading to costly fixings, downtime, and even endangerment of human lives. For that reason, inspectors play an essential role in the lifecycle of industrial components, providing assurance that the welding procedure provides the preferred toughness and longevity.

Furthermore, advanced technologies, such as phased selection ultrasonic screening and digital radiography, offer boosted capacities in discovering prospective weaknesses, permitting for corrective actions before problems escalate. By prioritizing the integrity of welds through precise assessment, industries can guarantee functional efficiency and prolong the longevity of their facilities.

Identifying Welding Flaws

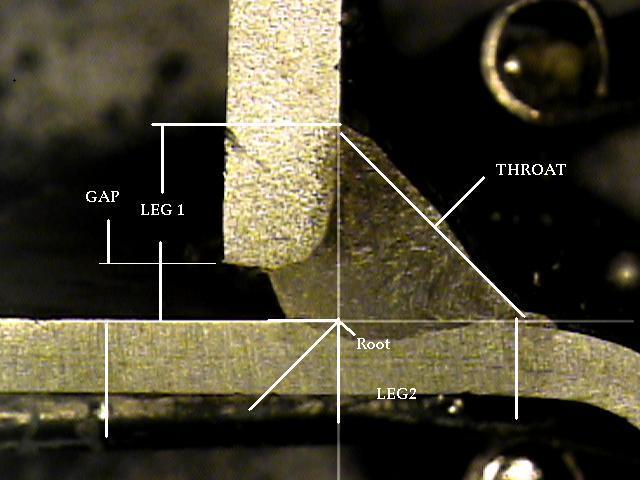

Determining welding flaws is a critical facet of making certain the safety and reliability of bonded frameworks. Usual welding flaws consist of porosity, fractures, incomplete fusion, and undercutting.

Skilled examiners make use of both aesthetic evaluation and progressed non-destructive screening (NDT) methods, such as ultrasonic or radiographic screening, to detect these problems. The prompt recognition and rectification of welding problems are critical to maintain the structural stability and long life of commercial components.

Guaranteeing Conformity Requirements

Maintaining the integrity of welded frameworks extends beyond determining flaws; it needs adherence to rigorous conformity criteria. Conformity with established standards, such as those offered by the American Welding Society (AWS) and the International Organization for Standardization (ISO), guarantees that welds satisfy minimum security and high quality demands. These requirements include a variety of requirements, consisting of material specs, welding procedures, and qualification of welders. Adherence to these standards is essential to avoid structural failures, which can bring about tragic effects in commercial applications.

Normal audits and examinations are vital in verifying conformity. Inspectors need to possess a thorough understanding of the appropriate criteria and be skilled at using different non-destructive screening (NDT) techniques to assess weld top quality. By guaranteeing that welding techniques align with conformity standards, business minimize the image source danger of non-conformity, which can bring about legal obligations and safety risks.

Furthermore, preserving compliance not just safeguards structural stability yet additionally enhances a business's reputation in the industry. Customers and stakeholders are most likely to trust fund firms that regularly show a dedication to quality and safety with extensive conformity. Hence, guaranteeing compliance requirements is a critical component in the successful application of welding in commercial applications.

Minimizing Upkeep Prices

The application of advanced non-destructive screening (NDT) methods, consisting of ultrasonic, radiographic, and magnetic particle examinations, improves the ability to find subsurface defects without compromising the architectural integrity of parts. By employing these methods, industries can substantially extend the solution life of their equipment, minimizing downtime and the associated monetary burden of maintenance tasks.

Additionally, a durable welding inspection routine supports the optimization of maintenance timetables, shifting from reactive to anticipating maintenance methods. This aggressive method not just stops unforeseen failings yet likewise enhances source allocation, making certain that maintenance initiatives are focused and efficient. Eventually, the investment in strenuous welding inspection is balanced out by the significant financial savings realized with lowered upkeep demands, contributing positively to the general functional performance of commercial enterprises.

Improving Safety Procedures

Although safety and security is a paramount issue in industrial operations, accomplishing ideal security criteria calls for a committed focus on the quality and reliability of welded structures. Welding inspection plays a vital function in this context, as it ensures that all joints and connections meet stringent safety criteria. Comprehensive inspections help identify defects such as cracks, porosity, or incomplete fusion that can endanger architectural stability. Such flaws, if left unaddressed, position significant risks, possibly bring about tragic failings.

Methods like ultrasonic testing, radiographic screening, and magnetic particle evaluation permit read review for detailed evaluation without harming the framework. Implementing a robust high quality control system that consists of normal training for welders and examiners makes sure adherence to developed safety standards.

Finally, promoting a society of safety and security within the company emphasizes the significance of complete welding examinations. Encouraging open communication and collaboration among examiners, welders, and engineers adds to a shared commitment to safety excellence. Welding Inspection Madison. In doing so, industries can safeguard their procedures, protect employees, and maintain public trust

Final Thought

Comprehensive welding evaluation is essential in industrial applications, dramatically boosting architectural integrity and reliability. By using sophisticated non-destructive testing methods, possible welding flaws such as cracks and insufficient blend are determined early, ensuring conformity with market standards and fostering customer trust. Strenuous assessments result in reduced upkeep costs and add to a much safer working environment. Inevitably, the thorough execution of welding examinations plays a vital role in keeping functional performance and security in commercial settings.

As we discover the multifaceted benefits of attentive welding inspections, one need to take into consideration the wider effects on safety, reliability, and cost-effectiveness in commercial procedures.

The key this content goal of welding evaluation is to make sure that the welds are qualified of bearing the expected stress and anxieties and loads they will experience in solution. Reliable welding examination plays an integral role in reducing these expenses by making sure the honesty and long life of welds, therefore mitigating the risk of premature failures.Comprehensive welding evaluation is vital in commercial applications, substantially boosting architectural stability and dependability. Eventually, the thorough execution of welding evaluations plays a vital function in preserving operational efficiency and safety in industrial setups.

Report this page