Why Pick Professional Welding Inspection Madison for Your Jobs

Why Pick Professional Welding Inspection Madison for Your Jobs

Blog Article

Understanding the Basics of Welding Assessment to Ensure Top Quality and Safety

In the realm of contemporary engineering, welding assessment stands as a foundation for ensuring both the quality and safety and security of structural productions. The process includes a precise evaluation of welded joints, utilizing sophisticated techniques such as ultrasonic and radiographic testing to identify hidden imperfections. The know-how of certified examiners is crucial, as they link the gap between academic requirements and sensible application. Their role extends beyond mere detection, including the documentation and interaction of searchings for to pertinent stakeholders. Yet, what are the subtleties of these assessment methods that make them important for preserving structural honesty?

Value of Welding Inspection

In the realm of commercial construction, the value of welding evaluation can not be overstated. Welding assessment plays an important function in making sure the honesty, safety and security, and longevity of bonded frameworks (Welding Inspection Madison).

The procedure of welding inherently entails complicated variables, including temperature, product residential properties, and environmental conditions, all of which can influence the top quality of the weld. A comprehensive examination determines flaws such as splits, porosity, and incomplete blend, which can jeopardize the strength and integrity of the weld. By spotting these issues early, rehabilitative actions can be taken, therefore lowering the threat of failure and linked costs.

Furthermore, welding evaluation adds to regulative compliance, as several industries are controlled by rigorous safety and security criteria and guidelines. Failure to stick to these regulations can result in economic penalties and legal obligations. Inevitably, welding assessment not just safeguards physical frameworks however additionally protects human lives and promotes market credibilities.

Key Welding Assessment Methods

Although welding evaluation is essential to guaranteeing the quality and safety of welded structures, it is the details methods used that identify the efficiency of the evaluation process. Key welding examination techniques can be extensively classified right into non-destructive screening (NDT) and devastating testing.

Magnetic bit screening and fluid penetrant testing are surface area evaluation approaches made use of to situate surface and near-surface defects. These comprehensive evaluation techniques make sure that welds satisfy market standards and safety needs, therefore making certain structural integrity and efficiency.

Duty of Certified Inspectors

Licensed assessors play a critical function in the welding assessment procedure, making certain that all welds adhere to rigid industry requirements and safety and security guidelines. Their competence is essential in recognizing flaws or irregularities that may endanger the architectural stability of a weld. By thoroughly taking a look at each weld, certified examiners aid stop possible failures that could bring about dangerous crashes or expensive repairs.

To become licensed, inspectors need to undertake rigorous training and screening, which acquaints them with numerous welding methods, materials, and screening methods. This detailed knowledge allows them to evaluate weld high quality successfully and make informed judgments concerning their safety and security and reliability. Furthermore, licensed inspectors are skilled in translating blueprints and requirements, guaranteeing that the welding work straightens with the task's layout needs.

An indispensable component of their role is to record their findings extensively, supplying a comprehensive document of the assessment procedure. Their contribution is crucial in keeping high degrees of high quality and safety and security in welding procedures.

Tools Utilized in Welding Examination

Welding inspectors rely upon a selection of specialized devices to execute their tasks efficiently, guaranteeing each weld satisfies the required criteria. Among these devices, visual inspection help like magnifying glasses and mirrors are fundamental, permitting inspectors to very closely examine welds for surface defects such as fractures, porosity, and undercut. Calipers and fillet weld determines are vital for measuring weld measurements to verify compliance with design specs.

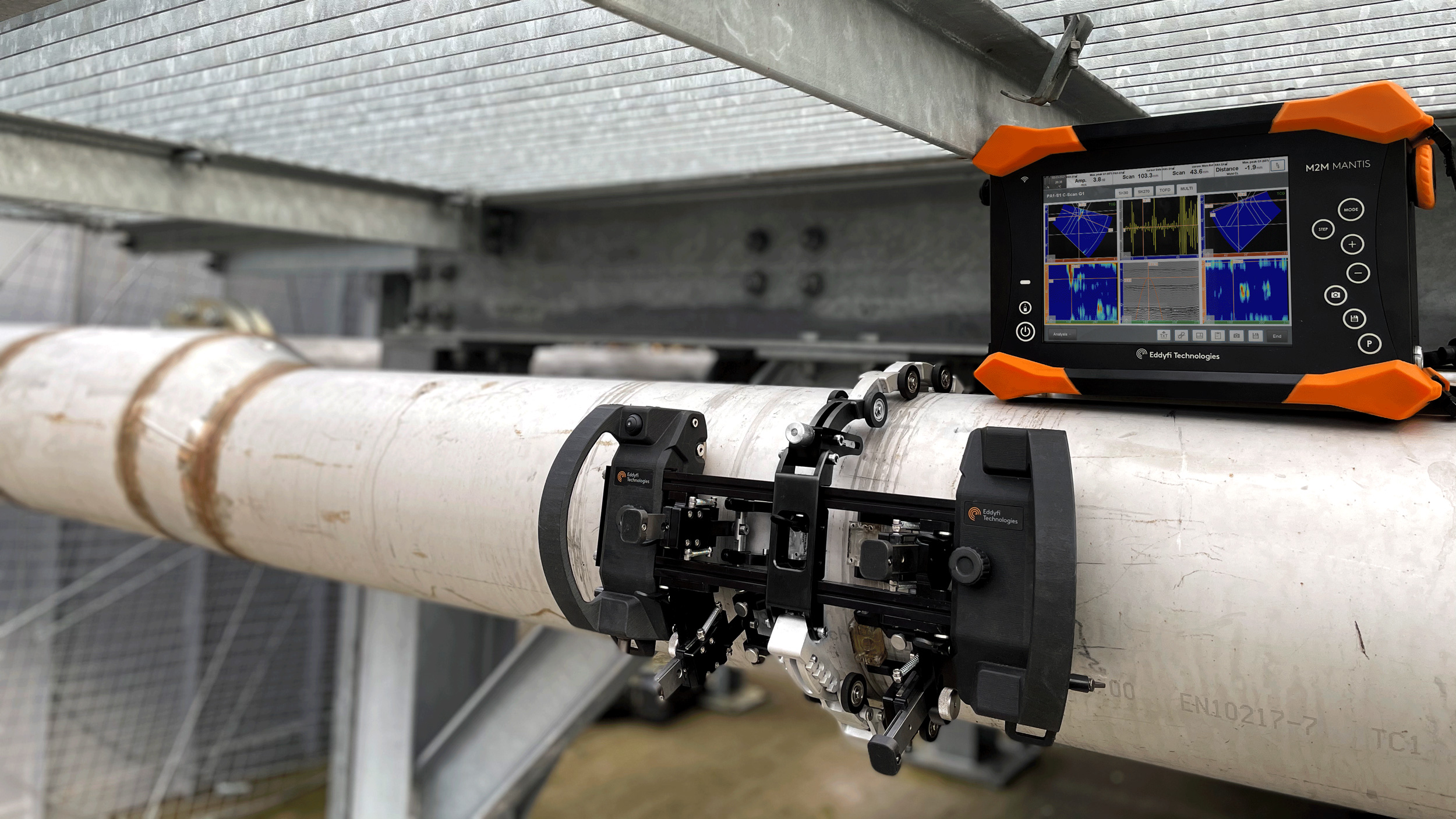

Advanced devices extend beyond visual help, consisting of non-destructive testing (NDT) devices. Ultrasonic testing gadgets are crucial in finding subsurface problems, using acoustic waves to expose inner discontinuities without endangering the weld's stability. Similarly, radiographic testing utilizes X-rays or gamma rays to capture images of a weld's inside, highlighting possible flaws.

Magnetic particle testing is another important device, specifically for detecting surface area and near-surface discontinuities in ferromagnetic materials. By applying magnetic areas and ferrous fragments, inspectors can identify imperfections that may otherwise be unnoticeable.

Dye penetrant evaluation is frequently made use of for non-ferrous products, offering a contrast-enhanced aesthetic check for surface-breaking defects. Welding Inspection Madison. Together, these devices make it possible for welding assessors to thoroughly examine weld top quality, making sure safety and security and integrity in various applications throughout industries

Making Certain Architectural Integrity

Welding procedures should stick to well-known standards and codes, such as those specified by the American Welding Society (AWS) or the International Organization for Standardization (ISO) These standards guarantee that the welds can endure environmental aspects and functional stresses. Certified index and licensed welders play an important role in this process, as their knowledge makes certain that methods are used properly, minimizing issues such as splits, porosity, and incomplete combination.

Post-weld inspection is one more crucial component of validating structural honesty. Non-destructive testing (NDT) methods, consisting of ultrasonic screening and radiographic screening, are used to discover subsurface imperfections without jeopardizing the welded structure. These assessments confirm that the welds fulfill the required quality requirements, supplying guarantee of their toughness and integrity. Inevitably, ensuring structural honesty in welding not just safeguards human lives yet likewise secures investments and improves the longevity of engineered structures.

Conclusion

The principles of welding evaluation are essential for keeping the top quality and safety of bonded structures. The use of specialized devices additionally improves the examination process, eventually safeguarding human lives and lengthening the life-span of bonded building and constructions.

Welding inspection plays an important role in ensuring the honesty, safety and security, and longevity of bonded structures.Although welding evaluation is crucial to making certain the top quality and security of bonded frameworks, it is the specific techniques utilized that determine the efficiency of the inspection procedure. Trick welding inspection approaches can be extensively classified into non-destructive testing (NDT) and harmful screening.Licensed inspectors play a pivotal role in the welding inspection process, making certain that all welds conform with stringent sector criteria and safety guidelines.The fundamentals of welding inspection are vital for keeping the quality and security of bonded frameworks.

Report this page